Kurashiki Hanpu (canvas)

The area surrounding Kurashiki city in the Okayama Prefecture is a major production area for canvas, accounting for about 70% of domestic production.

Since the Edo period, with extensive cotton plant cultivation carried out on land reclaimed from the estuary of the old Takahashigawa River, the techniques for intertwining thread to make string and bands was refined and production of canvas was developed following the end of the Meiji era.

The state of the factory – The machines have also been in use for nearly 100 years.

Since the old days, canvas has been used to make ship sails, horse harnesses and bags for students, due to its tightly woven and durable nature, ability to prevent water leakage and excellent air permeability.

Although kurashiki canvas boasts a high-quality level of manufacture domestically, there are three main characteristic points.

1. Abundance of types

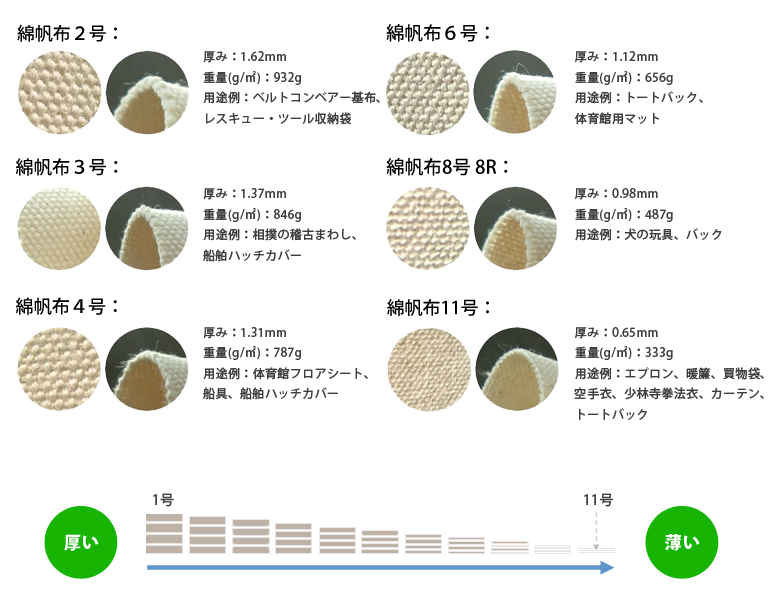

There are various types of canvas ,with levels of thickness ranging from 1 – 11. All the thicknesses are able to be manufactured due to the fact that all processes, such as the combining, intertwining and weaving of thread, are all carried out in a single factory.

2. Covers a wide range of applications from bags to conveyor belts

Obviously has application for use in general apparel such as familiar kinds of bags and shoes, but this also extends to a wider range of application for use in conveyor belts, loin cloths worn by sumo wrestlers, gym mats, sofa covers and curtains.

▼ Type of canvas and application (examples)

1号〜11号までの厚さの違いのイメージ。すべての帆布の厚みや用途について、株式会社タケヤリのサイトにて紹介されています。

3. Machines versus skilled craftsmen

Remaining unchanged for 130 years, all the manufacturing processes of kurashiki canvas are carried out through the effort of skilled craftsmen. The edge or ‘selvage’ of the material, having been inspected to ensure a strict level of quality, is uniform and perfectly seamless, and all the A quality products are then shipped.