Hello. The other day, we had a field trip to the factory where ARTSTEEL products are actually manufactured. We would like to report about how ARTSTEEL is made to everyone who is now thinking about ideas or applying.

Elaborate handiwork of craftsmen, not mass production

Many people may have an image of a dimly lit space filled with thunderous noise when they hear the word "factory", but this factory had a high ceiling, plenty of natural light, and a sense of openness. FRONT's art steel, being born in such a place, is indeed slowly handmade by craftsmen one at the time, and made us recognize anew the beauty of the material called iron, which we usually forget. We will actually show you a part of the manufacturing process in the factory, together with photos.

ARTSTEEL products go through two phases (factories) before they are completed.

(1) Shaping the material

(2) ARTSTEEL processing

Making the material

First, let's explain the process of making the material. The material is first manufactured from iron and later transformed into ARTSTEEL.

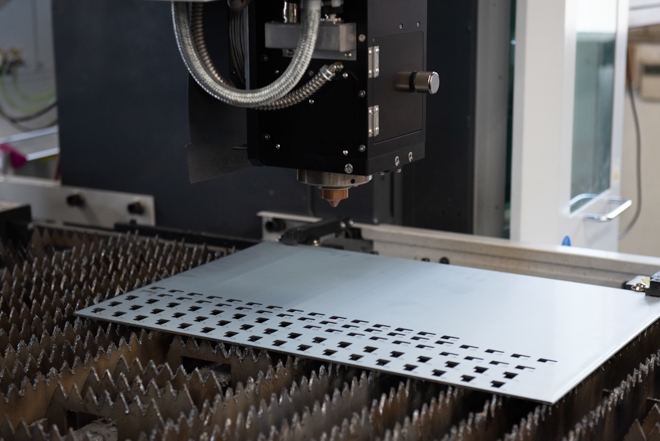

Making parts

Here, detailed parts are being created based on the uploaded data.

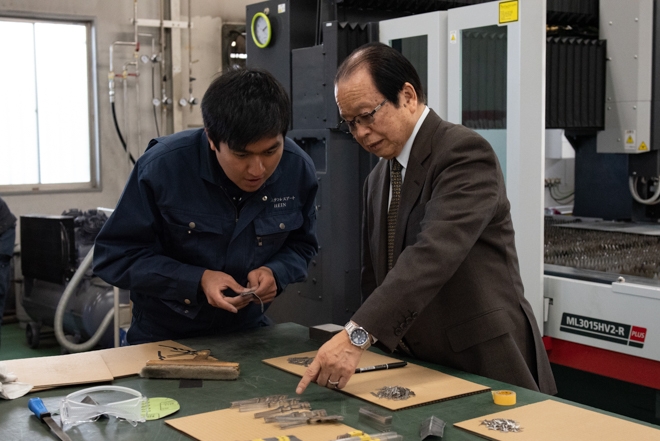

Checking, filing

The president is always frequenting the factory. We are making products while talking to the craftsmen on the actual site.

Polishing (form finishing)

Cutting

First, we processed the iron like this. The shape is made by making curved surfaces and polishing. Next, we will proceed with the processing that makes it into ARTSTEEL.

Processing ARTSTEEL

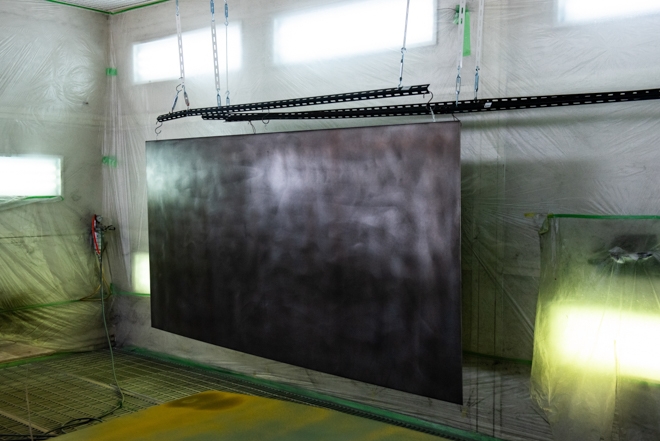

Next, we move on to the process that produces a feeling of rust and color. Out of the manufacturing processes of ARTSTEEL, what we want to show this time is especially how the rust is produced.

A repetition of "apply rusting agent, dry".

Rusting process 1

Rusting process 2

After the rusting agent is applied, it is neutralized, dried and finished with a special top coat.

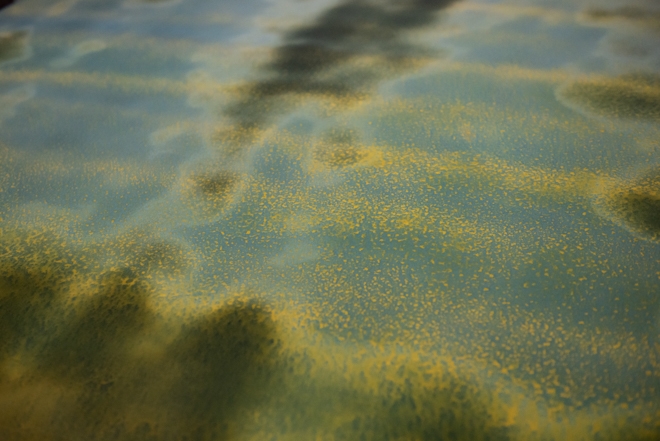

After a special phosphate coating treatment, original color is applied.

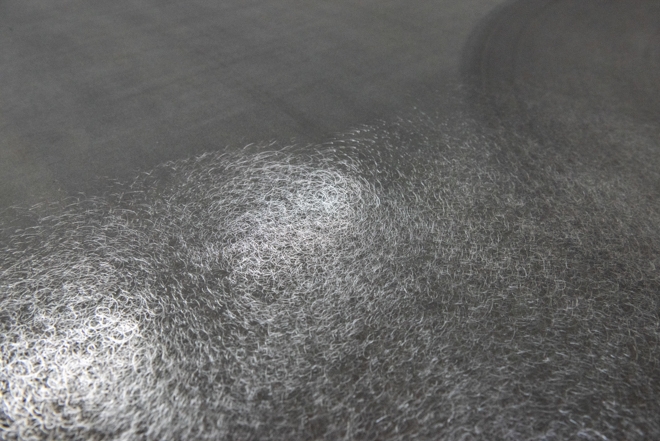

A pattern is made by drawing a circle over and over again.

The making of this pattern is different from mass producing the same pattern. No two patterns are the same, because the craftsman is drawing them one by one.

The difference of the surface before and after applying the pattern

We actually rented a machine and tried to make a pattern, but it immediately got uneven. It was very difficult to apply it with uniform force and in a level way. It was pure craftsmanship. Also, we learned that it can even be re-patterned after being used as a product. Reworking it after it has been used for a long time might also be a good idea.

Summary

"Art steel", the main building material of the products that we are looking for this time. In addition to the excellent functionality of the weather resistant steel, this factory tour also made us realize the breadth of possibilities in terms of expression, since no two pieces are the same. The products that the craftsmen are carefully making give a different impression depending on how the light hits and the viewing angle, making you grow fonder of them the more you look. They were a perfect match for art steel that can be used for a long time even when rusty.

The attraction of ARTSTEEL that I especially felt after visiting this factory is this:

(1) No two patterns are the same. Uniqueness is its charm.

(2) The manual work of craftsmen creates the beautiful expressions of ARTSTEEL.

(3) Even if it gets scratched once, it can be repolished and thus reborn as if it were brand new.

Also, if you would like to know more about ARTSTEEL, please come visit FRONT's showroom. You should be able to gain a deeper understanding of ARTSTEEL while actually touching it. If you let us know that you are applying for the contest, you will be able to discuss the details with the person in charge!

Please see this page regarding the showroom.

If you are thinking "I want to know now" / "I don't have time!", please see the video below.

https://www.youtube.com/watch?v=Rxzi9ZX1Dzg

This was the factory tour report.