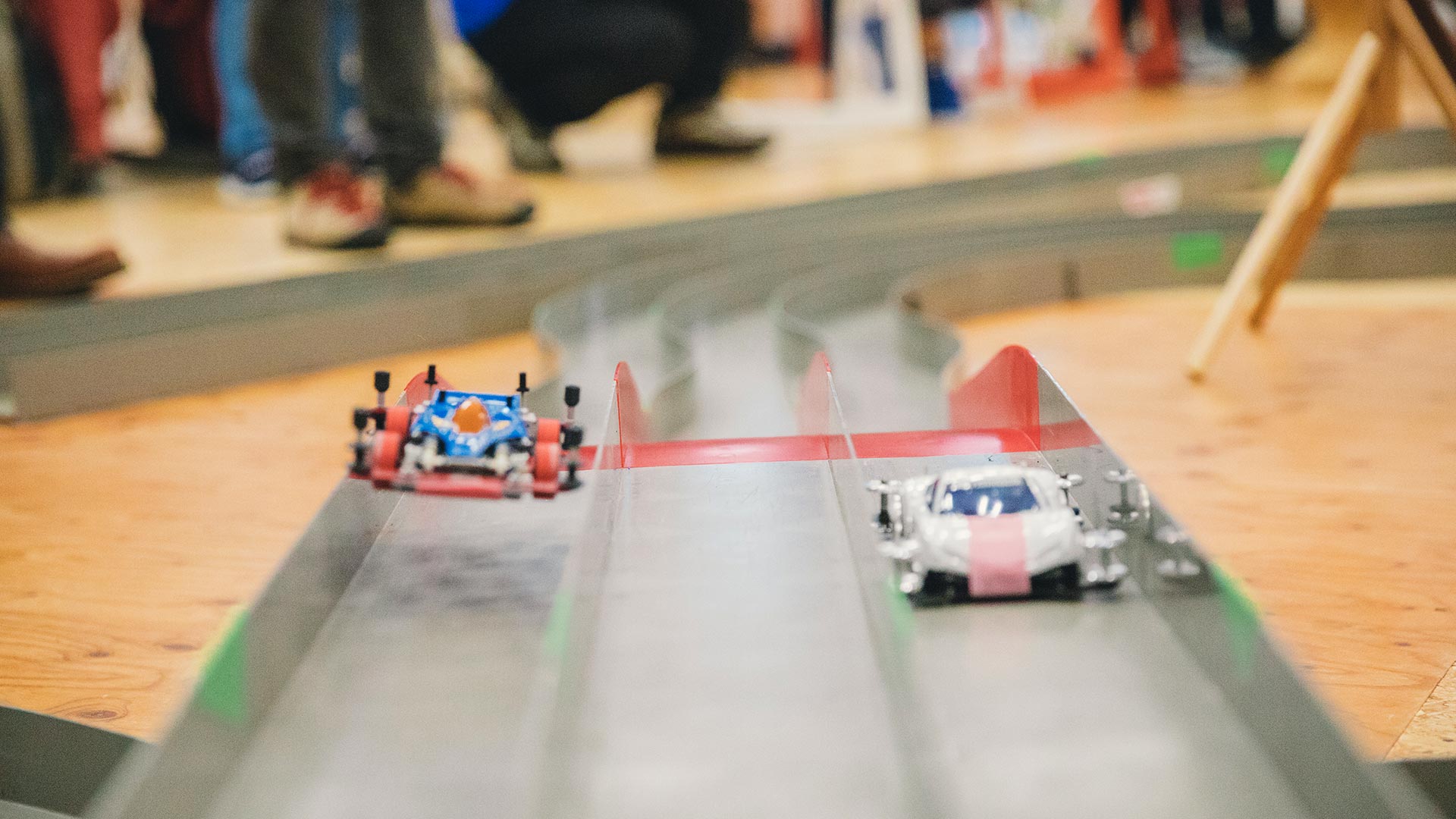

Hack Mini 4WD with precision processing technology in Suwa City, Nagano Prefecture!

Suwa City, Nagano Prefecture, where manufacturing companies with the highest precision processing technology in Japan are concentrated. Utilizing this technology, we will hold a tour & hackathon "SUWACKATHON" to create a special "Mini 4WD".

We are currently looking for creators to join SUWACKATHON. Cut, bend and polish your own mini 4WD with ultra-fine processing technology in micron units to create an innovative mini 4WD!

What are you doing?

SUWACKATHON participants will participate in a tour to Suwa City, Nagano Prefecture, and the Mini 4WD Hackathon in Tokyo by the following process.

Step 1: Factory tour and matching tour in Suwa City, Nagano Prefecture

On August 18th (Friday) to August 19th (Saturday), we visited 7 companies' factories with precision processing technology in Suwa City, Nagano Prefecture by bus tour. During the tour, matching will be performed to form a Mini 4WD team between the business operator and the participants.

Step 2: Prepare for the hackathon

The team is preparing for machine design and parts production for the hackathon. Each team will proceed with development in cooperation with Suwa operators.

Step 3: Hackathon, Mini 4WD production & race entry!

On October 14th and 15th, teams gathered again at a hackathon in Tokyo. A mini 4WD will be assembled and raced.

As a result of the review, the winning team will exhibit a work (Mini 4WD) at the Suwa Area Industrial Messe ( http://suwamesse.jp/ ) to be held in October. Award.

Recommended for such people!

・ Designers and engineers who want to connect with manufacturing companies with the highest precision processing technology in Japan

・ Creators and designers who want to make things using design and modeling technology

・ Engineers and designers from different industries who want to interact and connect with each other

・ People who are planning a new business in the company

Why Mini 4WD?

Mini 4WD is a small car. At first glance, this toy that looks like a child's play is currently evolving as creators and engineers from various industries compete for technology and pack various technologies into its small body.

SUWACKATHON is a collaborative project with Fab Racers , a global mini 4WD x manufacturing community where many engineers and industrial designers participate. Fab Racers has a Fab Mini 4WD Cup and workshops to broaden the monozukuri culture and take root. We aim to create new value by combining creative creators and engineers with highly technical businesses in Suwa City.

About Suwa City

After the war, the Suwa area in Nagano Prefecture, developed mainly in the production of watches, cameras, and music boxes, was called “Oriental Switzerland”. In the 2000s, we changed the industrial structure and made use of the ultra-fine processing technology cultivated in the manufacture of precision equipment, and shifted to the manufacture of high-precision industrial machinery and automobile-related parts that meet the needs of companies.

In the city, where many companies with the world's top processing technologies are located, the skills and “manufacturing DNA” are still handed down.

About SUWA design project

Suwa City, Nagano Prefecture, is a project that conveys the potential and appeal of Suwa City's high precision processing technology through matching and co-creation with manufacturing companies and creators in urban areas. This year, we will conduct a factory tour with engineers and creators from the Tokyo metropolitan area and human resources related to new business development under the theme of “Mini 4WD”. After that, mini 4WD utilizing precision technology will be produced at Hackathon, and the high precision processing technology of Suwa City will be widely communicated.

program

“SUWACKATHON” consists of two parts : a factory tour in Suwa City , Nagano Prefecture , and a hackathon in Tokyo . Participants are required to participate in both factory tours and hackathons.

Under the theme of “Mini 4WD”, we will tour the factory together with engineers and creators in the Tokyo metropolitan area and human resources related to new business development. After that, mini 4WD utilizing precision technology will be produced at Hackathon, and the high precision processing technology of Suwa City will be widely communicated.

Part 1 Factory tour and matching tour in Suwa City, Nagano Prefecture

Schedule: August 18 (Friday)-August 19 (Saturday)

● Stay in Suwa City for 2 days and 1 night to observe a factory of a manufacturing company in Suwa.

● Match Suwa manufacturing companies with creators to create a mini 4WD team. 3-5 creators form a team for one business.

● We will hold exchange meetings between participants and local people, and tours to experience the highlights of Suwa. In addition to plant tours, we will also have time to know about Suwa, such as places and shops that are currently being discussed.

Suwa has a higher altitude than urban areas such as Tokyo and Nagoya, and has low humidity even in summer. The nearby Kirigamine Plateau has been selected as a summer resort in midsummer, and in August fireworks display every day at Lake Suwa .

* Take a chartered bus from Shibuya and leave at around 8am on the 18th and return to Shibuya around 7pm on the 19th * Participation in the factory tour is mandatory. If you cannot participate, please contact us individually.

* Transportation and lodging expenses for factory tours are free and include lunch. Details will be given to participants.

Manufacturers to visit in Suwa

Komatsu Seiki Kosakusho Co., Ltd.

We produce ultrafine-grained stainless steel with a tensile strength 2 to 3 times that of normal stainless steel. Handles rods or wire rods of φ2.6mm or less, and plate materials of thickness 0.2mm or less. In addition, we are good at picosecond laser processing that enables high-precision processing on the order of µm and micro-texture structures.

Manufactures compression springs and tension springs with a line length of 80um-3mm.

Ultra-precision cutting technology with high technology in Suwa area, such as φ0.03mm fine hole cutting on 0.1mm thick stainless steel plate and Pyrex glass with 0.55mm pitch φ0.5mm hole group cutting. Have.

Has near field communication technology. We are good at battery-powered low power consumption systems, enabling integrated production from product planning to finished products.

Maruyasu Seiki Seisakusho Co., Ltd.

Specializes in processing external parts of metals by “super beautiful cutting”. We have high technology in decoration processing such as knurling, spinning, and diamond cutting.

High-quality, low-cost product manufacturing using the “Caulking Bonding” technology. We are developing the world's smallest sounding top, “sound top”.

Part 2 Hackathon in Tokyo @Yahoo! JAPAN “LODGE”

Schedule: October 14 (Sat)-October 15 (Sun)

● Participants and business teams that matched on the tour will gather again at the Hackathon in Tokyo to produce a mini 4WD.

● By the time the hackathon is held, each team will collaborate with Suwa operators to design machines and develop parts as necessary.

● On the day of the event, we will present the mini 4WD produced by each team and actually participate in the race.

● The award-winning works will be decided by the judges based on the presentation and the content of the race.

Application Guidelines

We are looking for engineers and creators to participate in plant tours held from August 18th (Friday) to 19th (Saturday), 2017 and “SUWACKATHON” held from October 14th to 15th.

What participants do

● Participate in the entire tour of the factory inspection and matching tour held in Suwa City from August 18 (Friday) to 19 (Saturday).

● In a joint team with a manufacturing company in Suwa City, determined through a factory inspection and matching tour, develop an original mini 4WD in cooperation with team members and participate in a hackathon on October 14-15.

* You will be responsible for all materials, processing costs and other costs associated with the Mini 4WD.

* Participation in plant tours held from August 18 (Friday) to 19 (Saturday) is mandatory. If you cannot participate, please contact us individually.

* Transportation and lodging expenses for factory tours are free. Details will be given to participants.

What the project supports

The project supports the following:

● Transportation and accommodation from Tokyo on a factory tour of a Suwa City manufacturing company from August 18 (Friday) to 19 (Saturday), lunch for two days.

● Support for team building and matching with manufacturing companies in Suwa City for hackathon participation.

● Factory tours in Suwa City and tours where you can experience the local attractions.

Application period

July 21, 2017 (Friday)-August 10, 2017 (Thursday) noon

Capacity

20 people * If there are many applicants, it will be a lottery.

Application conditions

● Person who can participate in factory visit of manufacturing company of Suwa City from Friday, August 18 to 19th (Saturday), 2017.

● Person who can participate in hackathon held from Saturday, October 14, 2017 to 15th Sunday.

● Those who have the ideas and skills to create a Mini 4WD.

* Please consult in advance if it is difficult to participate in a factory tour of a Suwa City manufacturing company.

award

Grand Prize : Production cost for 100,000 yen per team

Excellence Award : Production cost for 40,000 yen for 2 teams

Special Jury Prize : Production cost for 10,000 yen for 2 teams

Examination criteria

● Do you create innovative mini 4WDs that reflect the technology of Suwa City companies? ● Do you create mini 4WDs with original ideas?

Hackathon Judges

Kota Nezu

Creative communicator / Designer

Born in Tokyo in 1969. Graduated from Department of Industrial Design, Faculty of Engineering, Chiba University. Joined Toyota Motor and worked as a concept development leader for the “i-unit” Expo 2005 Aichi. Established znug design in 2005. Worked on the concept planning and design of many industrial products, contributing to the revitalization of creative activities of manufacturing companies. While promoting projects such as “zecOO”, an electric motorcycle with the concept of “From the Town Factory to the World” and “rimOnO”, a soft cloth ultra-compact mobility, the Toyota concept car “Camatte” “Setsuna”, Daihatsu Kogyo “COPEN”, THEMOS He develops mobile mugs “JMY”, “JNL”, Afternoon Tea lunch box “LUNCH WARE”, Tamiya Mini 4WD “Astralster” “RAIKIRI”. His works have been presented at design events in Japan and abroad, including Milan Salone del Mobile “Satellite” and Paris Maison et Objet Ministry of Economy, Trade and Industry “JAPAN DESIGN +”. Received Good Design Award, German iF Design Award, Japan Kansei Engineering Society Cute Sensitivity Design Best Award, JAPAN WOOD DESIGN AWARD Best Award (Minister of Agriculture, Forestry and Fisheries Award), JIDA MUSEUM SELECTION, etc. Member of the Good Design Award Jury since 2014.

Yuji Hara

Member of the Keio Research Institute at SFC/President and representative director of DiGINEL Co., Ltd. and DiGITAL ARTISAN Co., Ltd.

After getting a job at a prototyping site of a communication device manufacturer, he moved to a major 3D CAD / CAM manufacturer and experienced development managers, presidents of subsidiaries, and IR staff. He also founded 3D consulting and sales company K's Design Lab and represented the 12th term until the summer of 2017. Invented cutting RP and digital texture D3 Texture® and received the 2012 Tokyo Venture Technology Award Encouragement Award. Currently, he is working on the development of new processes, such as digitization of craftsmanship and discovery of new technologies, and proposes 3D digital manufacturing across fields, including corporate projects, art, medical care, and entertainment. In the summer of 2017, two new companies were established and started consulting services utilizing digital technology and support services by human resources with advanced digital skills.

Kentaro Minato

Amauchi Industry Co., Ltd. R&D Department R&D Managing Director

Born in Kyoto in 1983, raised in Nagano Prefecture (bred in Shinano Town, Nagano Prefecture). Worked at a precision sheet metal processing company in Shiga Prefecture and studied sheet metal processing. Joined Marine Industry from 2011. As a technology development department, Marine Industry is developing its own processing technology, such as the operation of WEB pages, the use of SNS, and participation in various projects.

JIMOCORO

Web media jointly operated by the local recruitment site “EIDEM” and Burg Hamburgburg Co., Ltd., which is good at making loose web content. It gathers and disseminates a number of stories that make you feel local love, such as attractive “places”, “work”, and “small newsletters” that are everywhere. The editor-in-chief is Tojiya Tojiro.

J-Kids

Creative production company such as advertising production, design, video, web, space production, J-KIDS RECORDS. At Suwa in Shinshu, we provide a variety of communication between people, things, and things, from start to finish, with careful consulting, vivid design, and detailed support.

Schedule

Application Deadline: August,10th,2017

Factory Visits: August,18th-19th,2017

Hackathon: October 14th-15th,2017

To this hackathon series page

Light Hack “Lightface”

2017 February 3rd-February 17th

SUWACKATHON

2017 July 21st Fri-August 10th Thurs